Instruct how to use ratchet tie down straps correctly and in detail✔️

- 1. What are ratchet tie down straps and applications?

- 2. Steps to use ratchet tie down straps?

- Step 1: Utilize the Release Catch to Open the Ratchet

- Step 2: Close and Rotate the Ratchet

- Step 3: Insert the Strap Through the Open Slot

- Step 4: Position the End-Fittings

- Step 5: Pull the Free End of the Strap

- Step 6: Tighten the Ratchet

- Step 7: Close and Secure the Ratchet Handle

- Step 8: Release the Strap

- Step 9: Post-Use Inspection and Storage

- 3. Question & Answer

- See more ratchet tie down straps products

Ratchet tie down straps are essential tools for securing loads during transportation. To ensure the safety of your cargo and those around you, it's crucial to use these straps correctly. This guide will provide step-by-step instructions on how to effectively use ratchet tie down straps.

1. What are ratchet tie down straps and applications?

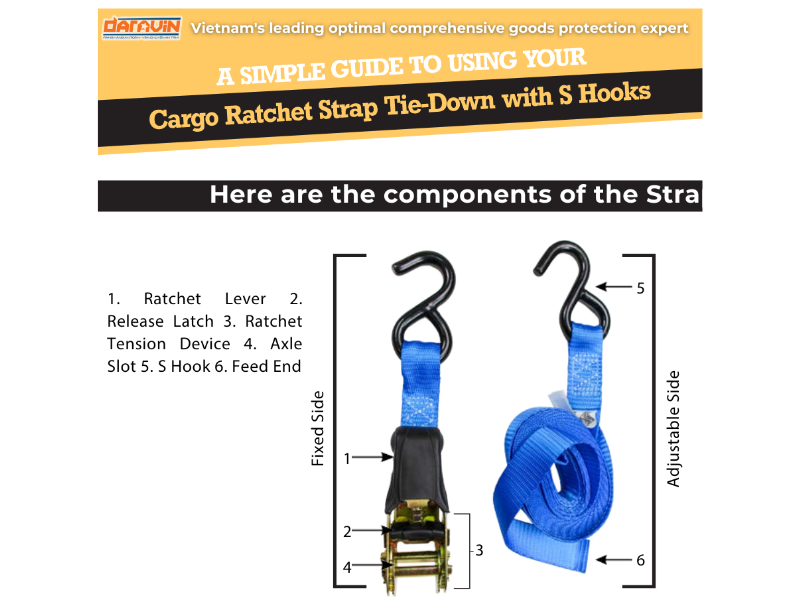

Ratchet tie-down straps are essential tools used for securing cargo during transportation. These straps feature a ratchet mechanism that allows users to tighten the strap with precision, ensuring that the load is firmly in place. They consist of a durable webbing material and metal hooks or end-fittings that attach to anchor points on a truck, trailer, or other vehicles.

Applications:

Cargo Securing: Ratchet tie-down straps are widely used to secure various types of cargo, from furniture and appliances to heavy machinery and vehicles. They prevent shifting and movement during transit, reducing the risk of damage or accidents.

Roof Racks: They are also employed for securing items on roof racks, such as bicycles, kayaks, or camping gear, providing a stable hold while traveling.

Transporting Goods: In industries like logistics and shipping, ratchet straps are crucial for safely transporting goods over long distances, ensuring that they arrive at their destination intact.

Overall, ratchet tie-down straps are versatile and reliable tools that play a vital role in cargo safety and transportation efficiency.

You can see details: What are a ratchet straps? Composition of the product

2. Steps to use ratchet tie down straps?

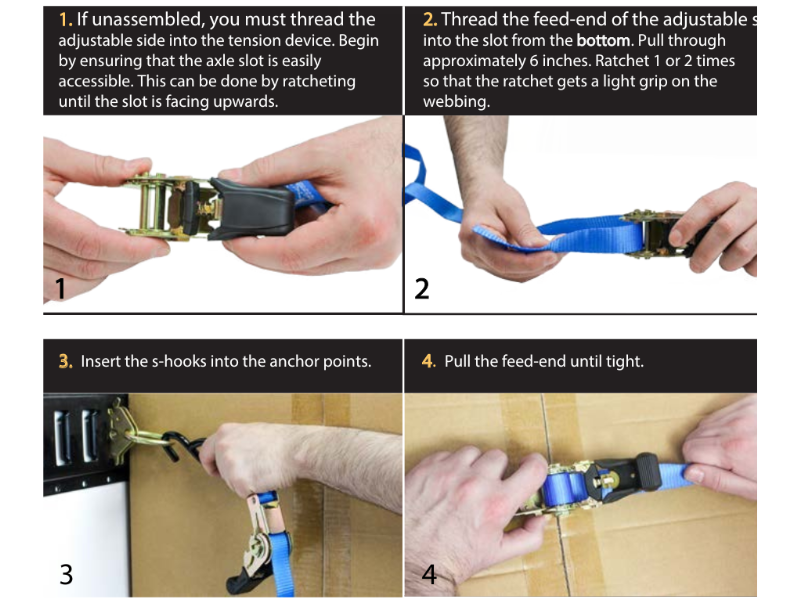

Step 1: Utilize the Release Catch to Open the Ratchet

Start by using the release catch, also known as the release lever, to lift the ratchet handle and axle simultaneously, positioning the open slot upwards. The release catch is situated at the center of the ratchet's movable top. This slot will be used for threading the strap in Step 3.

Step 2: Close and Rotate the Ratchet

Next, close the ratchet to gain access to the axle assembly. Pull up on the release catch and rotate the ratchet so that the cog wheels are facing upward.

Step 3: Insert the Strap Through the Open Slot

Take the strap and insert it through the open slot located at the bottom of the ratchet (mandrel). Guide the strap under the ratchet and feed it upwards through the slot. Wrap the strap around the axle, then pass the strap back through the same slot used initially. Ensure the strap lies flat and overlaps with the other half of the strap on the opposite side of the ratchet.

Step 4: Position the End-Fittings

Place the end-fittings, such as flat hooks or chain anchors, into their respective positions at both ends of the strap.

Step 5: Pull the Free End of the Strap

Pull the free end of the strap until it is tight, removing any slack between the strap's ends. Excess webbing left in the mandrel can cause the ratchet to jam when tightening. Remember that you can always adjust the tightness later, so focus on removing the slack for now.

Step 6: Tighten the Ratchet

Operate the ratchet handle to eliminate any remaining slack and tighten the strap. You should observe the strap wrapping around the axle. Stop tightening once the strap feels firm and secure. Avoid over-tightening, as excessive pressure may damage the cargo or break the strap. If you cannot fit at least one finger between the strap and the cargo, it is likely over-tightened, and you should loosen it. Aim for a secure fit that is not excessively tight.

Step 7: Close and Secure the Ratchet Handle

Once the strap is properly tightened, fully close the ratchet handle. Lock the strap by flipping the ratchet back into the closed position and pressing it until it latches. If you do not hear a click, check the strap and buckle to ensure they are secure. If the strap is loose, consider using a different ratchet strap as the current one may be faulty.

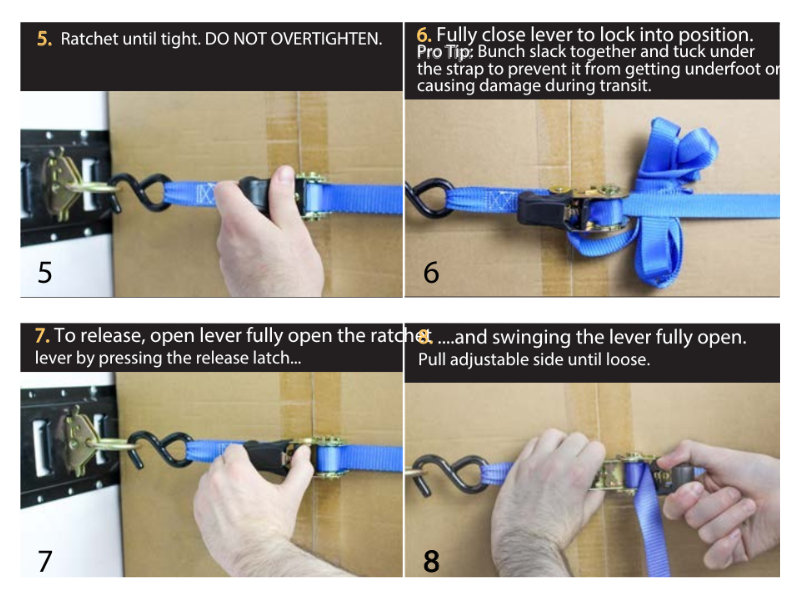

Step 8: Release the Strap

To release the strap, pull and hold the release handle. The release tab, located at the top of the ratchet, will disengage the locking mechanism and open the ratchet handle. The strap will then loosen, allowing you to pull it through the axle slot. Open the ratchet fully to remove the strap.

Step 9: Post-Use Inspection and Storage

After using the strap, wrap it up and secure it with a rubber band. Store the strap and ratchet mechanism in a dry container or bag. Inspect the strap and ratchet for any signs of wear, damage, or deformation. If you find any issues, replace the equipment before its next use.

See more video instructions at:

3. Question & Answer

How to Use Ratchet Straps on a Truck Trailer or Van

To secure your load in a truck or van, start by placing the ratchet strap over the cargo. Hook the ends of the strap over the sides of the truck bed or into the lashing rings/anchor points or grooves on the van's wall. Ratchet the strap until it is tight, ensuring that the load is firmly secured. Lock the strap into place securely. Using the appropriate number of straps will help you transport your cargo safely in the truck bed or van.

How to Connect Two Ratchet Straps Together

It is possible to connect two E-Track straps end-to-end, provided that they are designed for this purpose. However, connecting two straps will not give you an extended ratchet strap, which is best suited for small or flat cargo.

How Often Should Ratchet Straps Be Replaced?

With proper care, ratchet straps can last between 2 and 4 years. Do not use a strap that shows signs of wear, such as abrasions, cuts, or deformation of the hardware. Always inspect your straps and ratchets after each use and replace them immediately if any damage is detected.

How to Use Ratchet Straps on Roof Racks

Ratchet straps are ideal for securing cargo on roof racks. If your vehicle has a roof rack, loop the straps around the side and cross rails. Arrange the items evenly and centered on the roof. Place the straps over the cargo and tighten them, but avoid over-tightening to prevent damage to the items or the vehicle. Also, ensure you do not exceed the vehicle’s maximum load weight, which can be found in the owner’s manual. It’s a good practice to check the load after about ten minutes of driving. To further secure the load, consider covering it with a tarp or netting.

How to Undo Ratchet Straps?

To undo a ratchet strap, reverse the process used to secure it. Pull the release pin to flatten the ratchet handle, which will allow you to easily pull the strap back through.

Should Ratchet Straps Be Used for Slacklining?

Slacklining, which involves walking or balancing on a strap between two anchor points, uses a mechanism similar to ratchet straps. However, slackline straps are typically heavier-duty and designed specifically for this purpose. They often come with loops for secure attachment and are made to support a person’s full weight. Standard ratchet straps used for cargo are not suitable for slacklining as they are not designed to handle such loads. If you wish to try slacklining, invest in straps that are specifically made for this activity.

DARAVIN is the leading expert in providing optimal comprehensive cargo protection in Vietnam. With a long-standing brand, distributing millions of products each year, combined with hundreds of businesses, especially DARAVIN has a direct factory, so foreign businesses will receive discounts at optimal costs... Contact DARAVIN immediately for direct consultation and direct product experience.

main.comment_read_more